How AR is Making Warehouse Jobs Easier

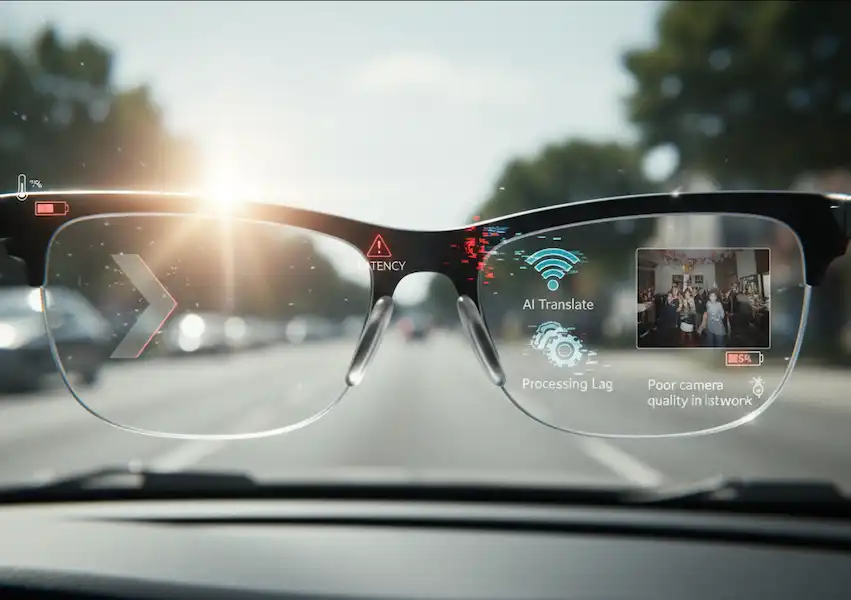

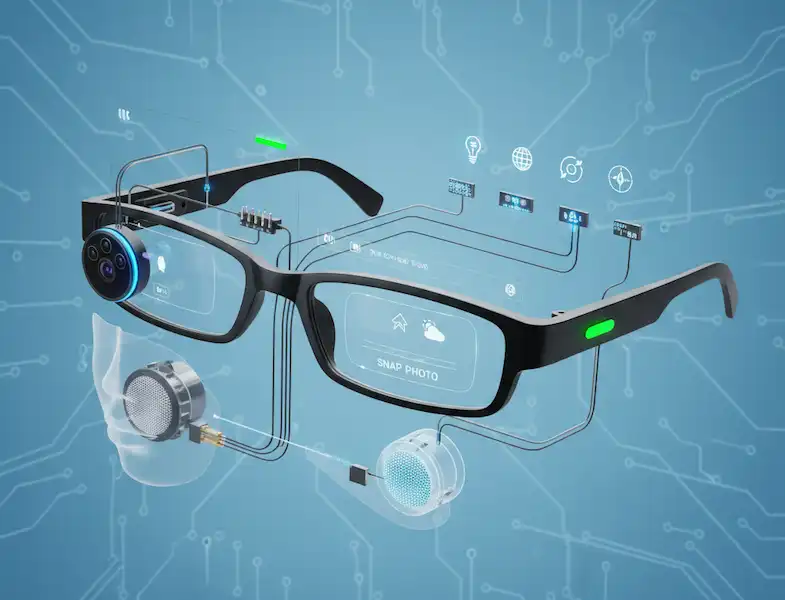

I recently saw a demonstration of Augmented Reality (AR) AR Smart Glasses in Warehouse Logistics in action, and honestly, it felt like something straight out of a sci-fi movie. Forget those massive, confusing handheld scanners and endless paper printouts. The warehouse floor is changing, and the new hero is a pair of AR Smart Glasses in Warehouse Logistics that literally guides workers with digital magic.

This isn’t just a tech upgrade; it’s a total reboot of how warehouse logistics works. It’s making jobs faster, safer, and a lot less frustrating for the people on the ground. Let me share how these “magic glasses” are actually making a difference, with some personal observations.

The Head-Up Display Like GPS for Picking Orders

Think about the most annoying part of shopping in a giant store: trying to find that one specific item tucked away on shelf 12B. Now imagine that’s your entire job, eight hours a day, rushing to meet deadlines. That’s the old warehouse reality.

With AR Smart Glasses in Warehouse Logistics, that stress melts away.

My Experience Watching It: I saw a picker put the AR Smart Glasses in Warehouse Logistics on, and instantly, a bright green arrow appeared in his vision, pointing him down the correct aisle. As he approached the rack, a rectangle highlighted the exact product box he needed, displaying the quantity right next to it—say, “Need 5.” It’s like having a floating checklist and a GPS system all rolled into one. He didn’t have to look down at a clipboard or scanner even once.

- Anecdote: A logistics manager I spoke to, Sarah, mentioned that before AR, a new hire would take weeks to get up to speed. “They’d spend half their time walking back and forth, confirming product codes,” she said. “Now, with the glasses, a person can be productive on day one. It cuts training time by nearly 50%.”

Key Impact Areas:

- Picking & Packing: This is the big one. It’s called “vision picking.” It basically removes the human error factor. If the glasses tell you to pick five blue widgets from the third shelf, you pick five blue widgets from the third shelf. No confusing product codes, no squinting at tiny labels.

- Inventory Checks (Stocktaking): Remember the dread of annual inventory where everyone just checks boxes? Now, a worker can walk down an aisle, and the glasses instantly show them the digital count for that shelf and flag any discrepancies. It’s the quickest way to see what’s physically there versus what the computer thinks is there.

Safety and Skill: Giving Workers a Helping Hand

Beyond speed, AR Smart Glasses in Warehouse Logistics are a major win for two crucial things: keeping people safe and sharing knowledge.

1. Real-Time Remote Expertise

This is perhaps the coolest feature for the maintenance crew.

- Anecdote: Imagine a critical conveyor belt breaks down. In the old days, you’d wait for the highly-paid, highly-specialized engineer to drive across town. Now, the technician on the floor puts on the AR Smart Glasses in Warehouse Logistics and calls the engineer via video. The engineer can see exactly what the technician sees and, here’s the magic part, can draw arrows and circles that appear in the technician’s actual view. “Look at the red valve, turn it counter-clockwise!”

This means downtime is slashed, and junior techs can tackle problems they couldn’t handle alone, making them feel more confident and skilled.

2. Better, Faster Training

Training in a warehouse usually involves thick manuals and shadowing someone who is already busy. It’s often inconsistent.

- Personal Insight: When I was learning a complicated task in an old facility, I wished I could just see the instructions floating over the machine. AR Smart Glasses in Warehouse Logistics does exactly that. It guides you step-by-step through complex procedures—whether it’s operating a forklift safely or assembling a custom package. It’s personalized, guided, and significantly speeds up the learning curve for new team members.

The Hard Numbers: Why Companies Love This

While the human element is important, the bottom line is what drives adoption. The benefits of AR Smart Glasses in Warehouse Logistics are easily quantifiable:

- Accuracy: Most companies report a massive drop in picking errors—sometimes by over 50%. Fewer errors mean fewer returns, happier customers, and less wasted time fixing mistakes.

- Speed: Picking speeds can increase by up to 25%. That’s a huge boost in productivity without requiring people to move faster or work harder—they just work smarter.

- Hands-Free: The biggest practical benefit. Workers have both hands available for lifting and moving items, which is safer and less cumbersome than juggling a scanner, a clipboard, and a box.

| Old Way (Handheld/Paper) | New Way (AR Smart Glasses) |

| Looking Down: Constant attention split between task and device. | Looking Up: Information overlaid; eyes stay focused on the work area. |

| Error Rate: Higher due to manual data entry and human misreads. | Error Rate: Significantly lower due to visual confirmation and guided steps. |

| Training: Time-consuming; requires trainers and rote memorization. | Training: Instant and intuitive; step-by-step guidance in real time. |

| Cost: Hidden cost of damaged scanners, printing, and fixing mistakes. | Cost: Upfront investment, but massive savings from efficiency and accuracy. |

FAQ

Q: Are these glasses heavy or uncomfortable?

A: They are getting much lighter. Manufacturers know workers wear these for full shifts, so ergonomics are a top priority. They feel similar to rugged safety goggles.

Q: Does the technology integrate with our current system?

A: Yes, almost all modern AR solutions are designed to “talk” to existing warehouse management software (WMS) or ERP systems. Think of the glasses as a new display screen for the data your system already uses.

Q: Is this just for giant corporations?

A: Initially, yes, but the technology is getting more accessible. Any warehouse dealing with high-volume, repetitive picking stands to gain huge benefits from AR, regardless of size.

Q: Will this replace human workers?

A: On the contrary. This technology empowers the human worker. It takes away the tedious, repetitive, error-prone parts of the job and lets people focus on the complex, critical tasks that still require human judgment. It’s about augmenting human capability, not replacing it.nect seamlessly with leading Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP) platforms.

Additional Helpful Links

- Learn how smart glasses have revolutionized healthcare – Smart Glasses in Healthcare: Enhancing Medical Practice

External Links for Authoritative Sources

- Zebra Technologies – Vision Picking: https://www.zebra.com/us/en/solutions/solutions-by-technology/ar-vr/vision-picking.html

- DHL – Augmented Reality in Logistics: https://www.dhl.com/global-en/home/insights/logistics-trends/augmented-reality.html

- Harvard Business Review – Augmented Reality for the Frontline Worker: (Search for “Harvard Business Review Augmented Reality Frontline Worker” as the direct link may vary over time)

- Statista – Market Size of Augmented Reality: (Search for “Statista Augmented Reality Market Size” for the latest reports)